PlantEye F500: Multispectral 3D Scanner for plants

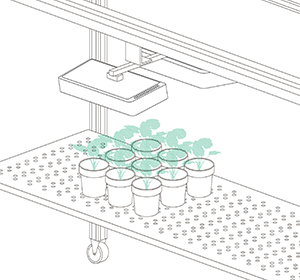

We combined the strength of 3D imaging with the power of spectral imaging in a single sensor – the PlantEye F500.

This page is outdated, please visit the PlantEye F500 page

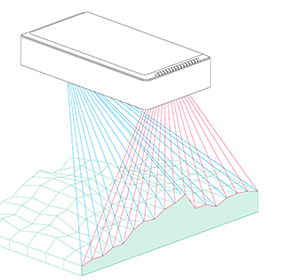

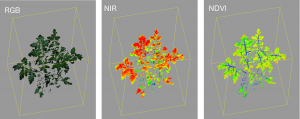

PlantEye F500 measures the 3D shape in high resolution and combines it on the fly with a 4-channel multispectral camera in the range between 400 – 900nm. This unique hardware-based sensor fusion concept allows us to deliver spectral information for each data point of the plant in X, Y, and Z-direction. This spectral information can now be easily corrected for angles and distances from the sensor using the depths information.

3D point cloud with different spectral information of a tomato plant capture with PlantEye F500.

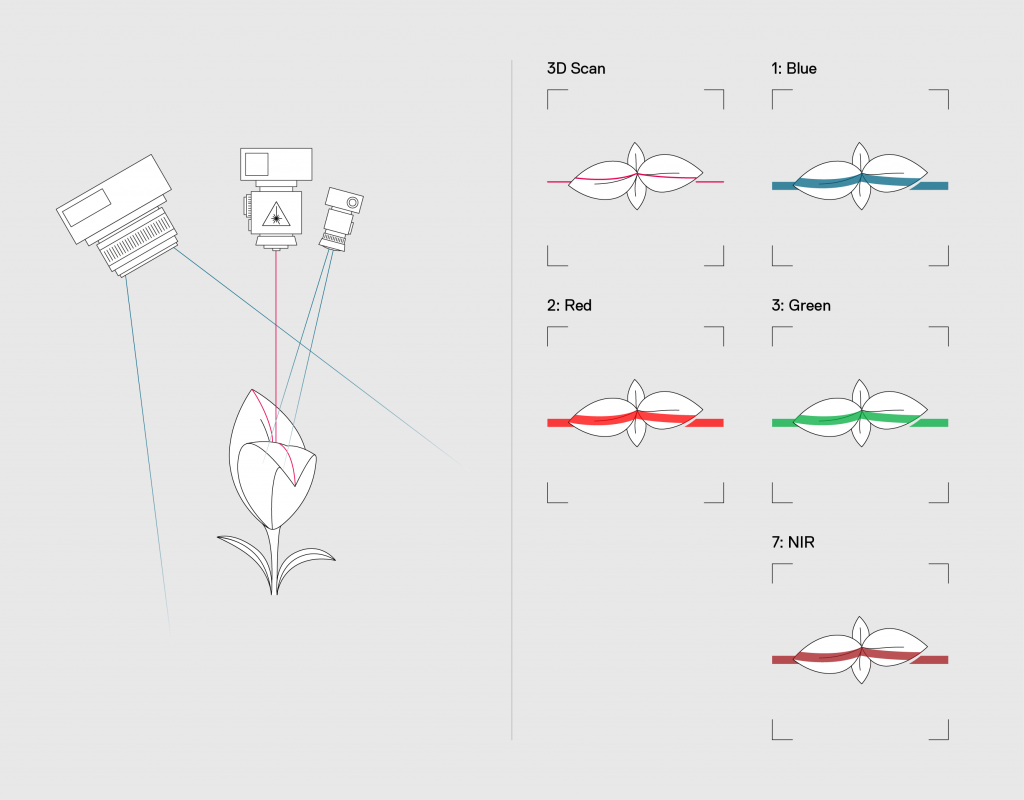

How does it work?

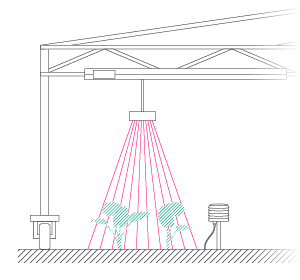

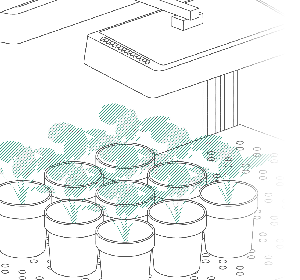

To provide this unique kind of scanner we combined our existing imaging concept of PlantEye with a multispectral flash unit that illuminates the plant and measures up to 4 wavelengths immediately after the 3D acquisition of the plant in high frequency. This way we can overlay 3D and multispectral information in one combined dataset without the need for computationally complex sensor fusion algorithms and provide both morphological and physiological parameters. Of course, we keep all key assets of the PlantEye F400 model and PlantEye F500 also works in all environments and can be operated in full sunlight.

In addition to the 3D scanning principle of PlantEye F400, PlantEye F500 adds a multispectral flash unit next to the laser. After acquiring the 3D information, this unit illuminates the scene with several colors. The images on the right show the view of the camera. For each color, one image is taken by the camera to measure the reflectance of the plant in that specific wavelength.

What parameter can we measure?

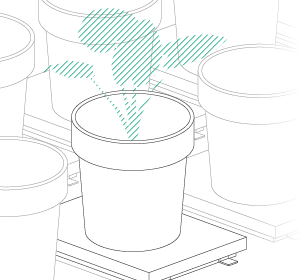

Previous PlantEye generations can compute automatically a wide variety of morphological parameters such as: Plant height, 3D leaf are, Projected leaf area, Digital biomass, Leaf inclination, Leaf area index, Light penetration depth, Leaf coverage.

In addition to that, PlantEye F500 can now measure a spectral reflectance for each point of the plant. Each wavelength can be statistically analyzed individually to calculate greenness, chlorophyll levels or to detect senescence. Next to that, wavelengths can be combined into spectral indices such as Normalized Digital Vegetation Index (NDVI), Enhanced vegetation index (EVI), Photochemical Reflectance Index (PRI) and many others. The wavelength the PlantEye measures can be chosen from a selection of available bandwidths to match the research application. Each point of the point cloud generated by PlantEye (stored as an open PLY format) contains:

-

X, Y, Z coordinates in space

-

Reflectance in Red, Green, Blue, and Near-Infrared

-

Reflectance of the 3D Laser (940nm)

-

Customization of the wavelength following your need and applications

Technical information of PlantEye F400 and F500

This page is outdated, please visit the PlantEye F500 page

PlantEye F400 |

PlantEye F500 |

||||

Morphological parameters |

9 |

10 |

|||

Spectral sensitivity |

940 nm |

380 – 900 nm |

|||

Spectral bands |

– |

up to 7 |

|||

Temperature control |

Laser temp stabilized |

Laser, LED & camera temp controlled |

|||

Weight |

5.1 kg |

5.3 kg |

|||

Dimensions |

420 x 200 x 92 mm |

440 x 210 x 99 mm |

|||

Input / Output |

Digital enable signalExternal trigger |

Digital enable signalExternal triggerRS232 / RS485*7 Channel Flash TTL Output |

|||

Measurement rate |

50 XZ-profiles / s |

50 XZ-profiles / s |

|||

Temperature range |

0…50 °C |

-10…50 °C |

|||

Humidity |

0 – 100% rel. |

0 – 100% rel. |

|||

Laser class |

1M |

1M |

|||

Power requirements |

24VDC or 230VAC |

24 VDC nominal10 – 36 VDC |

|||

Power consumption |

30 W |

50 W |

|||

Protection class |

IP 67 |

IP 65 |

|||

Connectivity |

WiFi |

WiFi, Ethernet |

|||

Y-Resolution (Vscan = 50mm/s) |

1 mm |

1 mm |

|||

Resolution (Z-Range 20cm) |

X |

0.22 mm |

0.19 mm |

||

Z |

< 0.1 mm |

< 0.1 mm |

|||

Resolution (Z-Range 120cm) |

X |

0.8 mm |

0.7 mm |

||

Z |

0.2 mm |

0.2 mm |

|||

Resolution (Z-Range 180cm) |

X |

1.8 mm |

1.5 mm |

||

Z |

0.5 mm |

0.5 mm |

|||